Gradient Controller

Gradient Controller

Gradient Controller

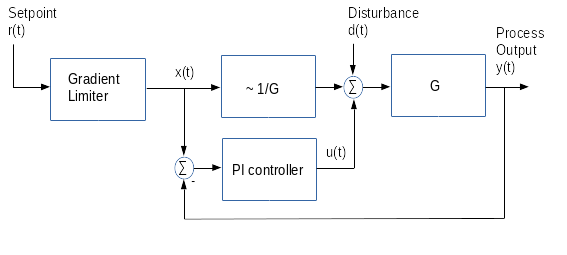

A gradient controller is a composite of a gradient limiter and a following feedback controller. The gradient limiter limits one or two derivatives of the setpoint. This may be used for a comfort increase of a speed controller or to reduce the wear of a power drive. Here the feedback controller for the process G is a PI controller with feed forward of the setpoint.

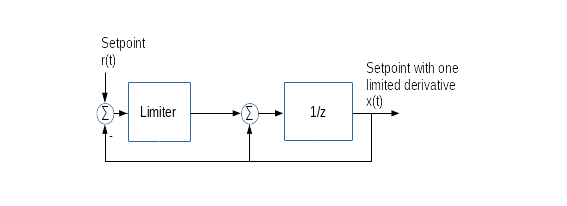

Gradient Limiter for one Derivative

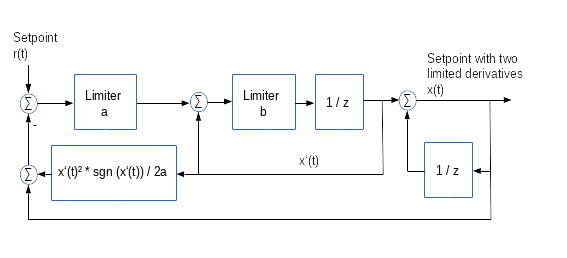

Gradient Limiter for two Derivatives

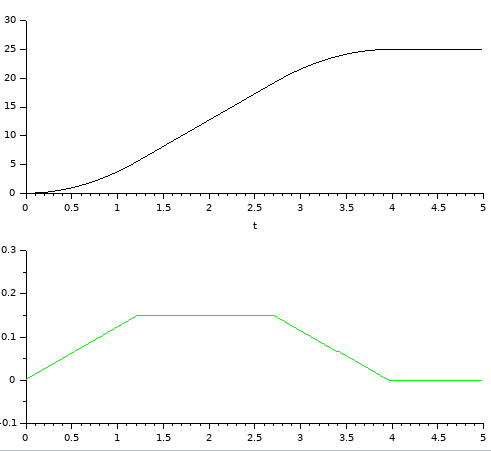

Step Response of a Gradient Limiter for two Derivatives

On top x(t) and below x'(t)